OUR CAPABILITIES

J&E Companies, through its R&B and J&E divisions, combine to create six manufacturing locations totaling over 450,000 sq. ft. of production space. The extensive capabilities offers our customers a wide range of precision metal and fabrication services.

For over six decades, we have excelled in providing an exceptional customer experience through manufacturing expertise and problem solving. Industries served include aerospace, automotive, agriculture, medical equipment, industrial equipment and appliances.

Our commitment to quality is underscored by our ISO 9001:2015 and AS 9001:2016 certified Quality Management System, which challenges us to continuously improve our processes to deliver the best parts to our customers.

CNC PROCESSES DELIVER ADVANTAGES

-

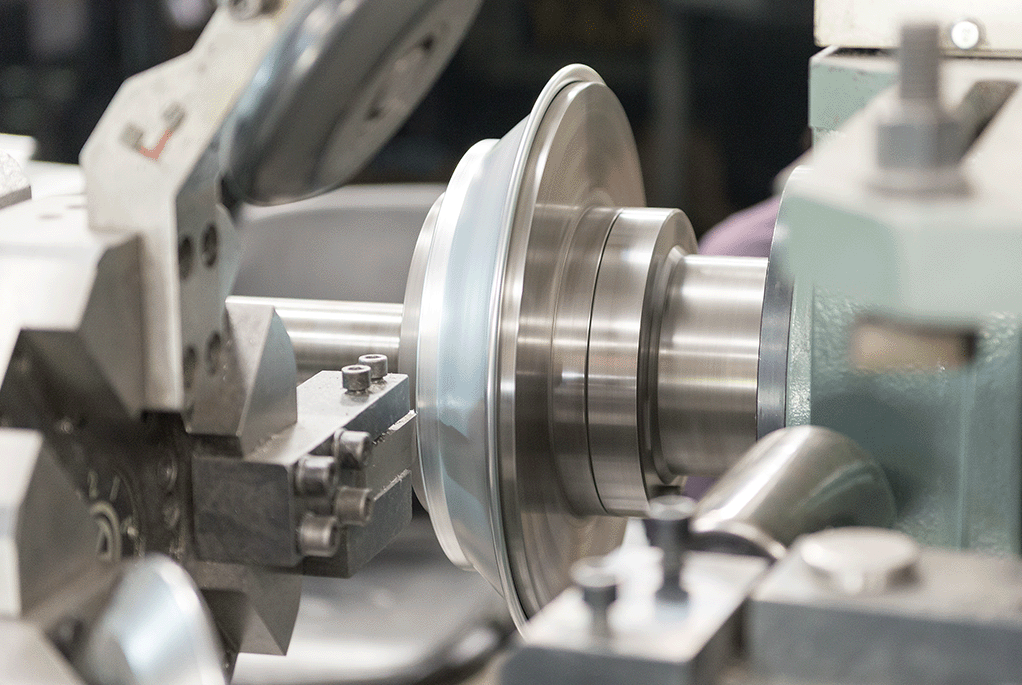

Turning

With an innovative combination of CNC Turning and Milling. our capacity and experience are unmatched. Along with cellular manufacturing, we build high quality parts with competitive pricing.

-

Grinding

J&E has expertise in all types of grinding that customers have come to expect, including Infeed, Endfeed, Thru Feed, Cylindrical, Internal and Blanchard grinding.

-

Milling

Manufacturing close tolerance CNC machined components with an innovative combination of CNC Turning and CNC Milling enables us to offer competitive costs for high-quality parts.

vertically integrated PROCESSES

-

BROACHING

Multiple broaching machines add speed and efficiency to the manufacturing process. Vertical integration of all manufacturing departments offers unique and cost-effective solutions for OEMs.

-

WELDING

Full Robotic, Manual Mig and Tig, and Spot welding production capabilities. Added value opportunities through custom designed fixtures often lower costs and shorten lead times.

-

AUTOMATIC SCREW MACHINES

Designed to remove material at a highly efficient rate while holding tight tolerances creates a highly efficient process with competitive pricing that enables secondary operations.

-

Sheet Metal

Multiple facilities and a large arsenal of fabrication equipment can deliver a high volume of sheet metal components and assemblies. Quality, efficiency, and material utilization are top priorities.

-

Powder Coating

Three in-house powder coating shops ingrained into our facilities equipped to provide quality-tested pretreatment processes and state-of-the-art metal finishing. Precision and durability are guaranteed.

-

Metal Spinning

We offer an extensive library of standard tooling and custom tooling capabilities. Metal spinning is a cost effective way to improve manufacturability of axially symmetrical parts for extreme precision.