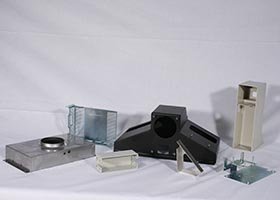

Precision Fabrication Services for Custom Medical Devices and Metal Enclosures

Today’s custom medical enclosures are often highly complex, requiring intricate CAD designs that specify a multitude of precision-machined features with tight tolerances.

Custom Fabrication Services for Agriculture and Farming Equipment

Specialized agricultural equipment manufacturers such as J&E Companies help your enterprise achieve its production goals through our complete range of metal fabrication, CNC machining, and custom welding services.

Custom Fabrication Services for Commercial Kiosks and Enclosures

J&E Companies fabricates commercial kiosks and various retail enclosures for use in rugged, high-traffic consumer environments.

Automated Panel Bending – Advantages of CNC Sheet Metal Forming

Factory automation is the key to offering precision, consistency, and cost-effectiveness in the modern field of industrial sheet metal fabrication. Compared to conventional / manual metal forming operations, the repeatability of CNC sheet metal forming services can provide higher quality products at higher volumes with quicker turnaround times.

Fiber Optic Laser Cutting Services – Advantages & Applications

Fiber optic laser cutting systems are one of the many state-of-the-art tools available to modern CNC fabrication shops. Compared to traditional metal cutting solutions, laser cutting services have the capability to be both quicker and more accurate. These advanced metalworking tools perform close-tolerance cuts at rapid speeds.

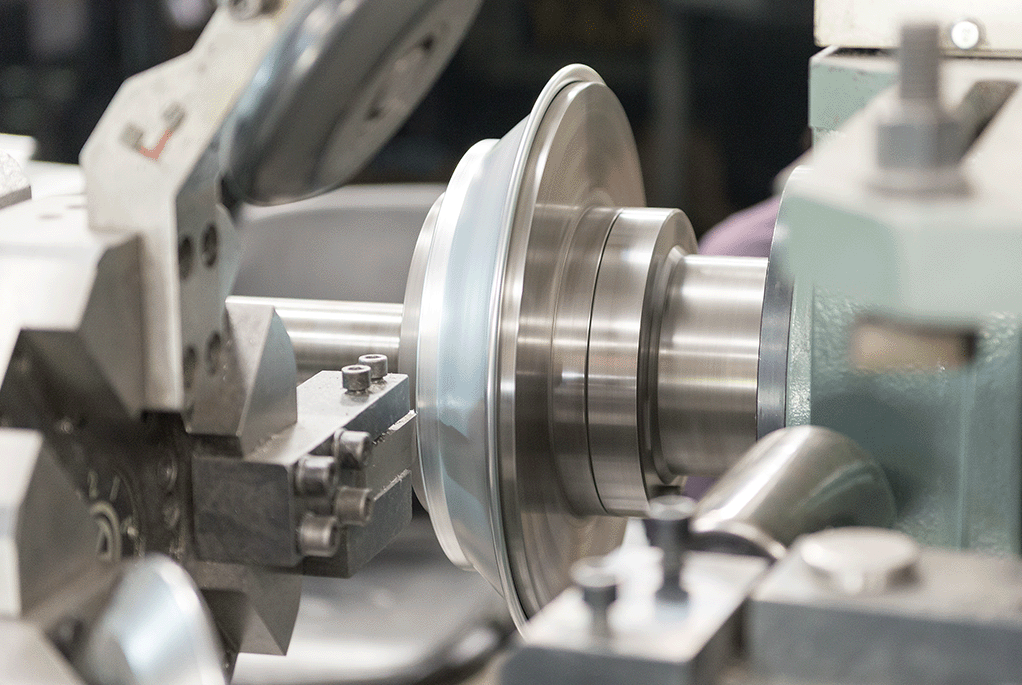

What Is Metal Spinning? An Overview of the Process & Benefits

Metal spinning is a complex metalworking service is used to manufacture axially symmetric parts from round metal discs, tubes, or cylindrical blanks. Metal spinning services can be performed both manually and via CNC lathe. Spinning is a reliable and efficient service that J&E Companies utilizes for complex custom metal components and prototypes.

The Advantages and Applications of 5-Axis CNC Machining Services

Precision Multi-Axis Machining Solutions For Complex Components and Assemblies Traditionally, CNC machining systems were generally restricted to 3-axis operations. Even in the modern machining industry, 3-axis machines are still used in many applications. After all, they are almost always cheaper and simpler than their 5-axis counterparts.

The Difference Between a Conventional Mazak Lathe and a Swiss Turning Machine

Swiss turning machines operate differently than conventional CNC lathes in a number of ways. Both conventional and Swiss turning operations are subtractive machining processes: a centrally held workpiece spins, while precision grinding and cutting tools are positioned to carefully chisel away material.

Stainless Steel Refinishing Services for Commercial and Industrial Projects

A Guide to Common Stainless Steel Finishes Utilized Throughout the Industry Stainless steel provides a number of material benefits to commercial and industrial manufacturing projects. Like many other quality steel alloys, stainless steel offers high strength combined with outstanding resistance to rust, chemicals, and corrosion.

Engineering for Optimum Manufacturability

An Overview of Design for Manufacturing (DFM) – Methods and Advantages Engineering your product designs for optimum manufacturability paves the way for a streamlined overall production process. When it comes to your custom machined products and metal stampings, streamlining the manufacturing process equates to lower costs and higher consistency

The CNC Turning vs. CNC Milling Process

What’s the Difference Between CNC Milling and Turning Services? CNC turning services and CNC milling services are two of the most common machining processes used throughout the modern manufacturing industry. As their names suggest, both of these services are guided by advanced computer numerical control (CNC) technology.

How to Increase Efficiency and Sustainability in Sheet Metal Production?

Developing More Flexible, Efficient, and Sustainable Sheet Metal Fabrication Services Precision fabrication technology combined with streamlined CAD design and engineering systems enable manufacturers like J&E to maximize both quality and efficiency throughout the sheet metal production process. In the modern world of metalworking and fabrication services, automated production technology is increasingly put to use